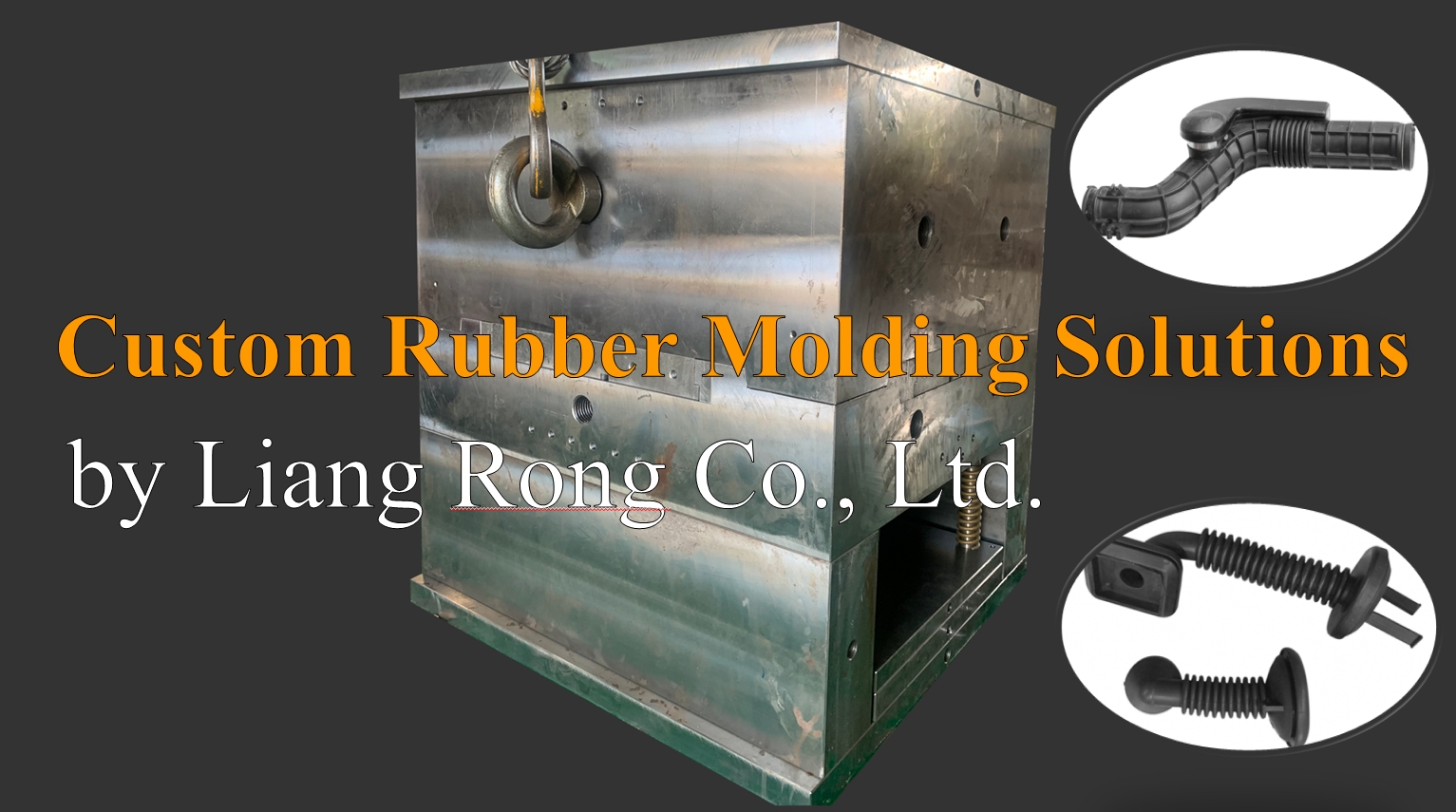

Custom Rubber Molding Solutions by Liang Rong Co., Ltd.

Introduction

Custom rubber molding is a specialized process that involves shaping rubber into specific designs using precision molds. This technique allows for the production of high-quality rubber parts tailored to diverse industrial applications. At Liang Rong Co., Ltd., we excel in providing design services (DFM), mold development, and production for both plastic and rubber products. Our services include double-package, two-color, two-material plastic injection, and insert injection molding. We also offer CNC integrated milling and fixture machining, enhancing the precision and efficiency of our manufacturing solutions. Our commitment to innovation and quality positions us as a leader in custom rubber molding, meeting the complex needs of our clients with expertise and reliability.

What is Custom Rubber Molding?

Custom rubber molding involves creating rubber parts and components based on specific design requirements. This process uses molds that are uniquely designed and manufactured to produce parts that precisely match the desired specifications, including size, shape, and material properties. Custom rubber molding is essential for producing parts that must meet strict performance criteria, such as seals, gaskets, and other critical components used in automotive, industrial, medical, and consumer products.

Types of Custom Rubber Molding

- Compression Molding: Ideal for producing simple and complex rubber parts in small to medium volumes. It involves placing pre-heated rubber into a mold cavity and then applying pressure to shape the part.

- Injection Molding: A high-efficiency process suitable for large-scale production. It injects heated rubber material into a mold cavity, allowing for precise and intricate designs.

- Transfer Molding: Combines aspects of compression and injection molding, allowing for the production of complex shapes and materials with embedded components.

Benefits of Custom Rubber Molding

- Design Flexibility: Custom rubber molding allows for the creation of parts with complex geometries and unique features that standard processes cannot achieve.

- Material Versatility: A wide range of rubber materials can be used, including natural rubber, silicone, EPDM, nitrile, and neoprene, each offering distinct properties like heat resistance, chemical resistance, and flexibility.

- Cost-Effective Production: By creating molds specific to your needs, custom rubber molding minimizes material waste and optimizes production efficiency, reducing overall costs.

- High Precision and Consistency: Our advanced molding techniques ensure each part meets exact specifications, maintaining high quality across all production runs.

Applications of Custom Rubber Molding

Custom rubber molding is widely used across various industries:

- Automotive: Manufacturing seals, gaskets, bushings, and vibration dampening components that require precise tolerances and durability.

- Industrial: Producing parts for machinery, such as o-rings, washers, and grommets, that must withstand harsh operating conditions.

- Medical Devices: Creating components for medical equipment, such as seals, diaphragms, and connectors, where hygiene and biocompatibility are essential.

- Consumer Goods: Developing custom parts for household items, electronics, and sports equipment, ensuring product performance and user safety.

Why Choose Liang Rong Co., Ltd. for Custom Rubber Molding?

At Liang Rong Co., Ltd., we are committed to delivering high-quality custom rubber molding solutions tailored to the unique needs of each client. Our state-of-the-art facilities and experienced team ensure that every project is executed with precision and attention to detail. We offer:

- Expert Consultation: From material selection to mold design, our experts work closely with you to ensure the best outcomes for your project.

- Advanced Technology: Utilizing the latest molding technologies, we ensure that every part meets the highest standards of quality and performance.

- Reliable Service: We pride ourselves on our timely delivery and excellent customer service, providing support throughout the entire manufacturing process.

Conclusion

Custom rubber molding is an essential process for creating specialized rubber components that meet exact specifications and performance requirements. At Liang Rong Co., Ltd., we are dedicated to providing top-tier custom rubber molding solutions that help our clients achieve their manufacturing goals. Contact us today to learn more about our custom rubber molding services and how we can assist with your next project.