Injection mold type (2) Three-plate mold

Three-plate mold

Add a stripper plate that can be restricted to move between the fixed installation plate and fixed plate. When the mold is opened, the vertical sprue and runner are separated from the product by the sprue puller pin, and then the stripper push the runner separated from the sprue puller pin. The three-time mold opening sequence is a three-plate mold, which is usually used for pin-point gate or multi-cavity molds.

Advantages:

*The gate arrangement position of the three-plate mold can be varied.

*Without manual removing the runners.

*Small gate mark on the part.

Disadvantages:

*It will produce more waste than hot runner mold or two-plate mold.

*Large injection pressure loss.

*Higher cost than two-plate mold molds.

What situations to select three-plate mold:

1. The gate needs to be on the top of the product:

If the product needs to be gated at the top.

2. The appearance needs perfect gate marks:

Pin-point gate can be easily hidden in decoration or text, leaving a perfect gate mark.

3. Need to automatically cut off the gate:

The runner and the product can be automatically separated when the three-plate mold is opened.

4. When the number of cavity is an important factor:

If you need to increase the number of mold cavities but do not want to increase the size of the mold, you can use a three-plate mold to place the runner and the finished product on different mold surfaces to increase the number of mold cavities without increasing the width of the mold.

5. When the clamping force is affected:

The runner system in the two-plate mold is on the same plane, which will increase the overall projected area and therefore increase the required clamping force. The runner system of the three-plate mold is not on the same plane as the product, so the clamping force will not increase.

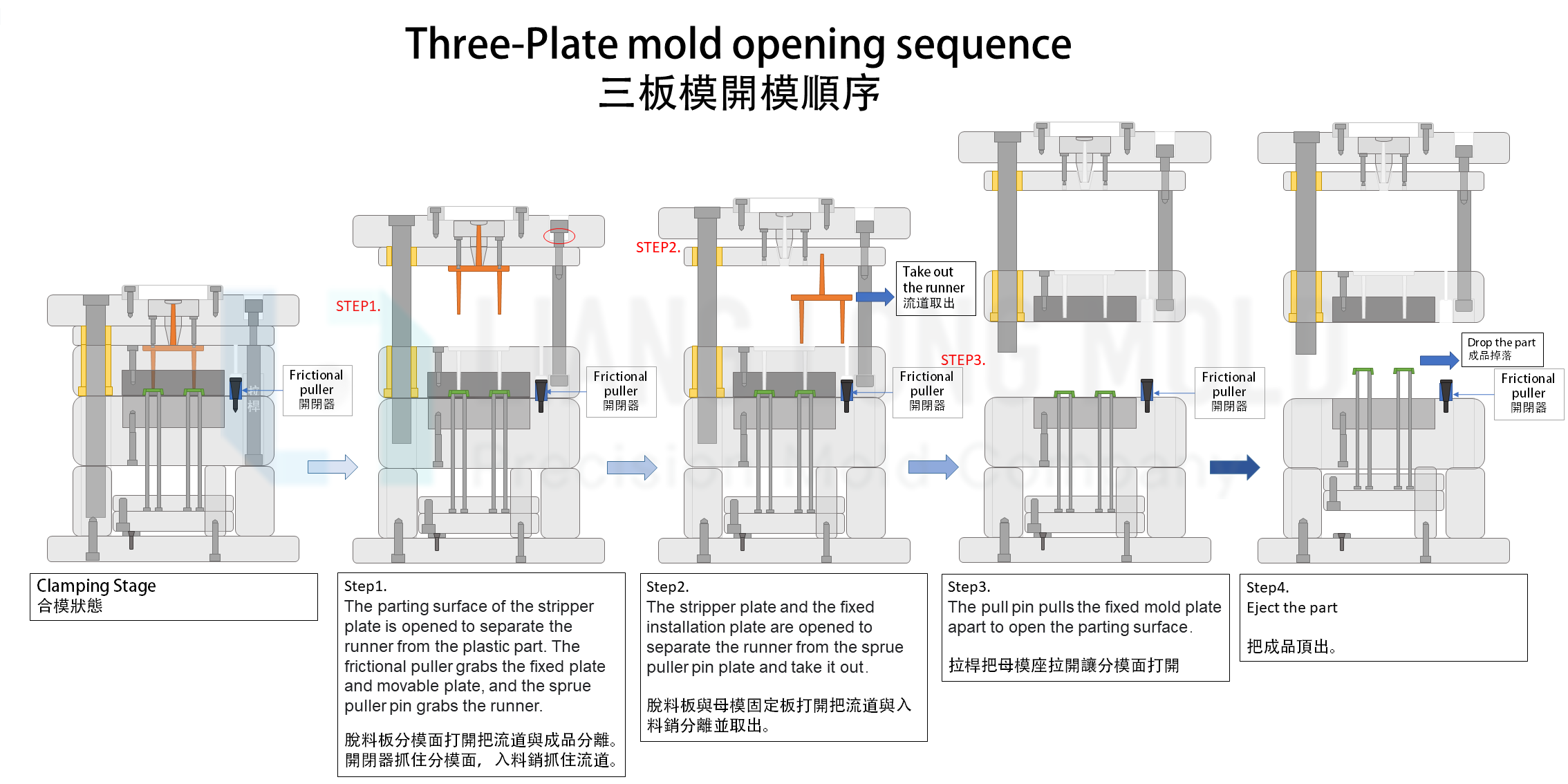

Three-Plate mold opening sequence:

STEP1.

The parting surface of the stripper plate is opened to separate the runner from the plastic part. The frictional puller grabs the fixed plate and movable plate together, and the sprue puller pin grabs the runner.

STEP2.

The stripper plate and the fixed installation plate are opened a small gap to separate the runner from the sprue puller pin plate and take it out .

STEP3.

The pull pin pulls the fixed mold plate apart to open the parting surface of the mold .

STEP4.

Eject the part.